The Wagenborg fleet of the future

How can we make sure that our fleet continues to meet the needs of our clients in times of sustainability demands? That is the central issue for the Wagenborg fleet strategy. In conversation with Theo Klimp, fleet director of Wagenborg Shipping.

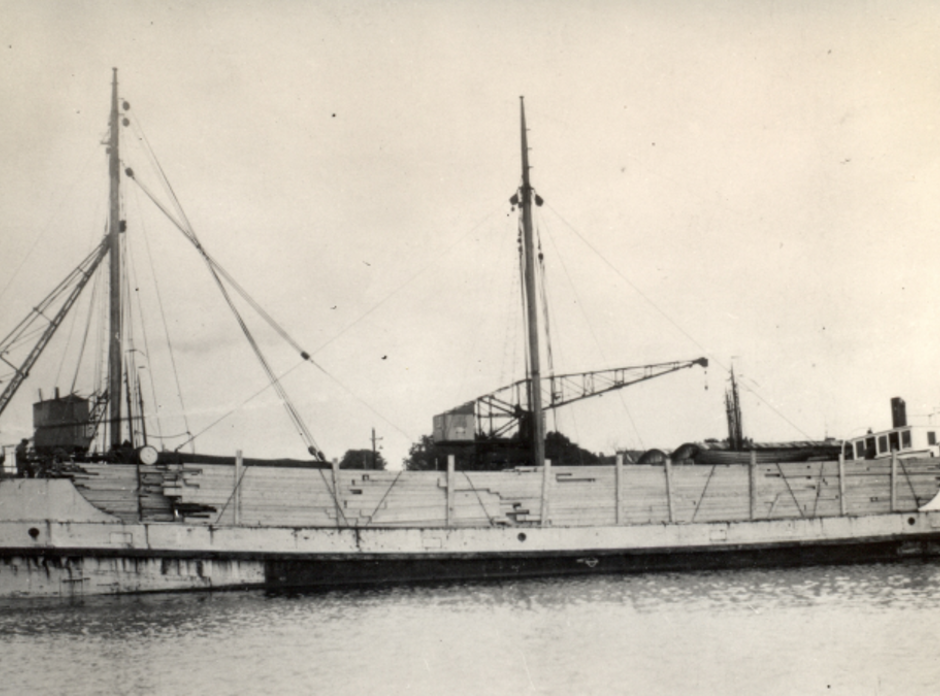

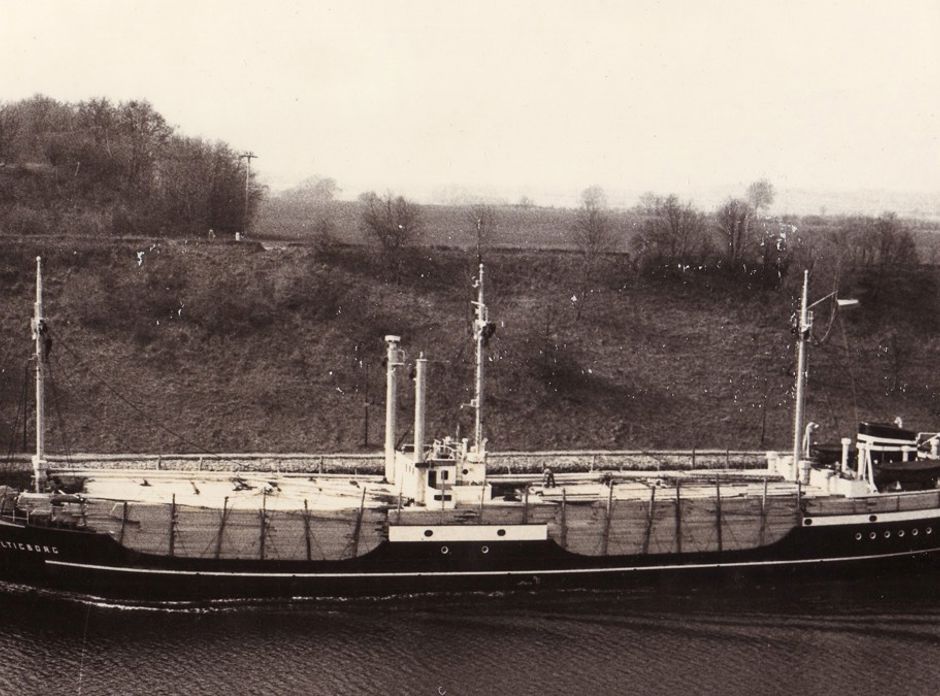

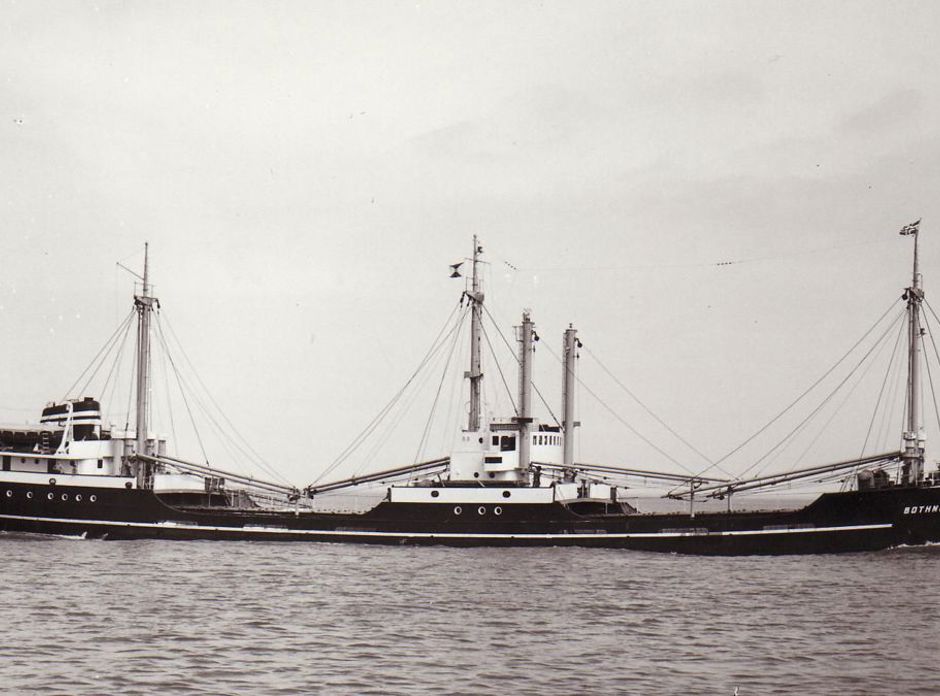

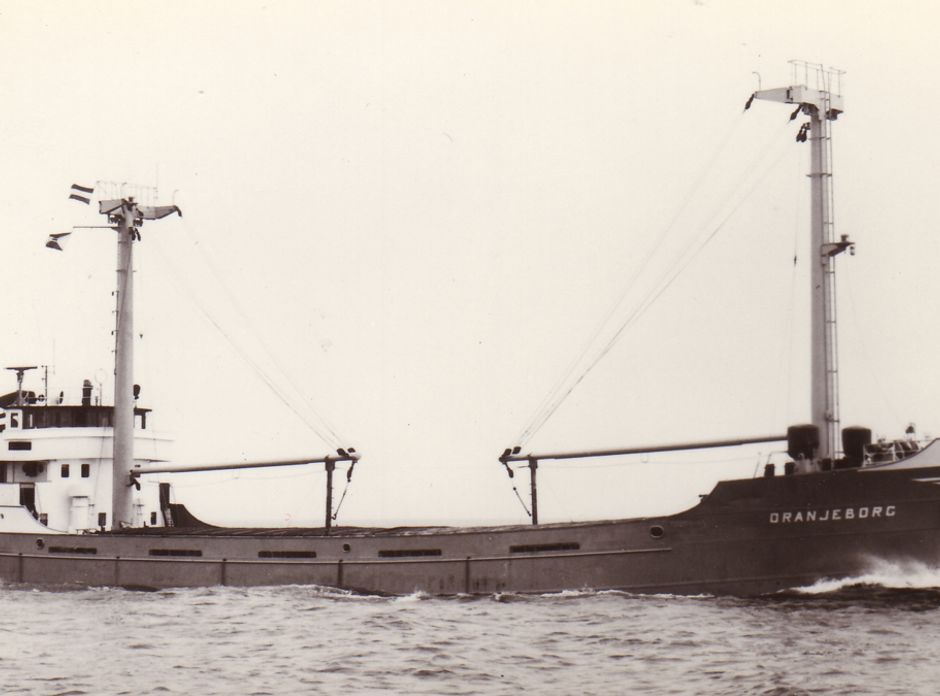

“Over the past 125 years, Wagenborg has always been at the forefront of fleet innovations. That is in the family genes, a clear vision of where we want to be as Wagenborg ”, is how fleet director Theo Klimp kicks off the conversation. “That led to the construction of the Oranjeborg and Kroonborg in the 1950s, with an unparalleled cargo capacity for that time, and the construction of our first EasyMax ‘Egbert Wagenborg’ in 2017, an award-winning vessel that others are still trying to copy. They are choices that have taken us to where we are today: an important player in general cargo. We now have all the knowledge, expertise and ideas that are in the heads of our people embedded in a fleet plan.”

Standardisation

What does the fleet of the future look like? “I can't spill all the beans”, smiles Klimp. “But we need more standardisation for starters. We now have around 160 dry-cargo vessels in our fleet, spread across 46 types. That is not practical for planning, which needs to take account of the different tonnages and dimensions of the vessels. And it's far from ideal for the crew and the colleagues of technical maintenance. They need to familiarise themselves with a different vessel every time. Based on client needs, we have determined a number of types of different tonnages that we want to operate in the future.” The vessels will be characterised by the familiar Wagenborg principles, such as right-angled holds with a large hold content, a minimum engine capacity to reduce emission, ice class 1A, and dimensions in line with our sailing area.

Based on client needs, we have determined a number of types of different tonnages that we want to operate in the future.

Time

“This won't happen from one day to the next”, emphasises Klimp. “We invested in our vessels on time. As a result, our fleet already complies with the standards and requirements of the future. That is proven by the CII, a kind of energy label for vessels. With an average of 16 years, our vessels are relatively young too. Our angle is to have the vessels sailing until they are 30 at least. We invest in that. Every five years we carry out a major overhaul and that goes beyond returning a vessel to good condition. We carry out technical updates, so that our vessels are modern and remain reliable. It all means we have time.”

That time comes in handy right now whilst there is so much uncertainty about the fuel of the future. “That is the biggest challenge we are faced with. We want to do more than just limit CO2 emissions, we are looking at the emission of other harmful substances across the entire cycle, it needs to be safe, available in our sailing areas, and energy density is an important criterion too. There are plenty of ideas, lots of testing is going on, but the solution hasn't been found yet. If we'd start building now, we are certain to have to convert in a few years’ time. That's why we are opting to build one EasyMax per year for the time being. The EasyMax design has room in the aft for modifications. We did the same with ballast water before. By setting aside room in advance, you create options for building in and conversions. And by continuing to build, we do have the opportunity to test things out and to innovate. When the time is ripe, we’ll scale up.”

If we'd start building now, we are certain to have to convert in a few years time.

Efficiency

That doesn't mean that Wagenborg is complacent about sustainability. “We have reduced our relative CO2 emissions compared to 2008 by 26% already and with efficiency improvements in behaviour and technology, for example with smart investments that facilitate more economical sailing, and with just-in-time agreements with our clients so that we can adjust our sailing speeds accordingly. It is possible to achieve much more in those areas. I’ll hazard a guess that with fuel efficiency, mixing in biofuel and other savings methods, we will achieve our target of 40% CO2 reduction in 2030.”